college preparatory Coaching and Training for middle and high school athletes

Champions aren’t born—they’re built. They’re shaped in environments that push limits, demand excellence, and foster growth. That’s exactly what we do.

St. Christopher Academy isn’t just a training academy. It’s a proving ground for student-athletes who refuse to settle. Here, we combine high-level basketball development with a structured foundation, giving young athletes the tools to compete—on the court and in life.

This is where drive meets direction. This is where the work gets done.

If you’re serious about taking your game—and your future—to the next level, we want to hear from you.

Complete the interest form today. Your journey starts now.

In Partnership With

A Legacy of Leadership And Transformation

Brian L. Clifton

Coach Brian Clifton has guided some of the sport’s brightest stars.

John Wall - Kentucky / Washington Wizards

Ryan Kelley - Duke / Los Angeles Lakers

Quincy Miller - Baylor / Denver Nuggets

Darius Morris - Michigan / Los Angeles Lakers

Sam Grooms - Oklahoma

Marshall Moses - Oklahoma State

J.T. Terrell - Wake Forest / USC

Brandon Huffman - UNC Chapel Hill

Evan Johnson - Maryland Eastern Shore

Eric Wallace - Ohio State

Sean Carter - Oregon State

Stargell Love - Baylor

Anthony Fields - Wake Forest

Quddus Bello - Baylor

Jalen Harris - Arkansas

Max Farthing - NCSU

Blake Harris - NCSU

Sam Montgomery - LSU (Football)

Brian’s work isn’t just about the big names. It’s about every athlete who’s willing to put in the work, embrace the grind, and commit to their journey. He believes every young player deserves a shot at success—not just in basketball, but in life.

Draft day picture of Brian Clifton with #1 pick John Wall.

Photo Credit: Kyle Gustafson

More Than a Student. More Than an Athlete. Prepared for Life.

At St. Christopher Academy, we know that success isn’t just about making the shot or passing a test—it’s about preparing for the demands of college and beyond. That’s where Dr. Kim Brodie comes in. As a seasoned Learning and Curriculum Development Specialist, Higher Education Professional, and Health Education Specialist, she helps bridge the gap between high school and college by equipping our student-athletes with the academic structure, life skills, and mental resilience they need to thrive.

In this video, Dr. Brodie breaks down why traditional academics aren’t enough and how our holistic approach ensures that every athlete is ready for the next level—not just in their sport, but in life.

EDUCATION BUILT FOR ATHLETES

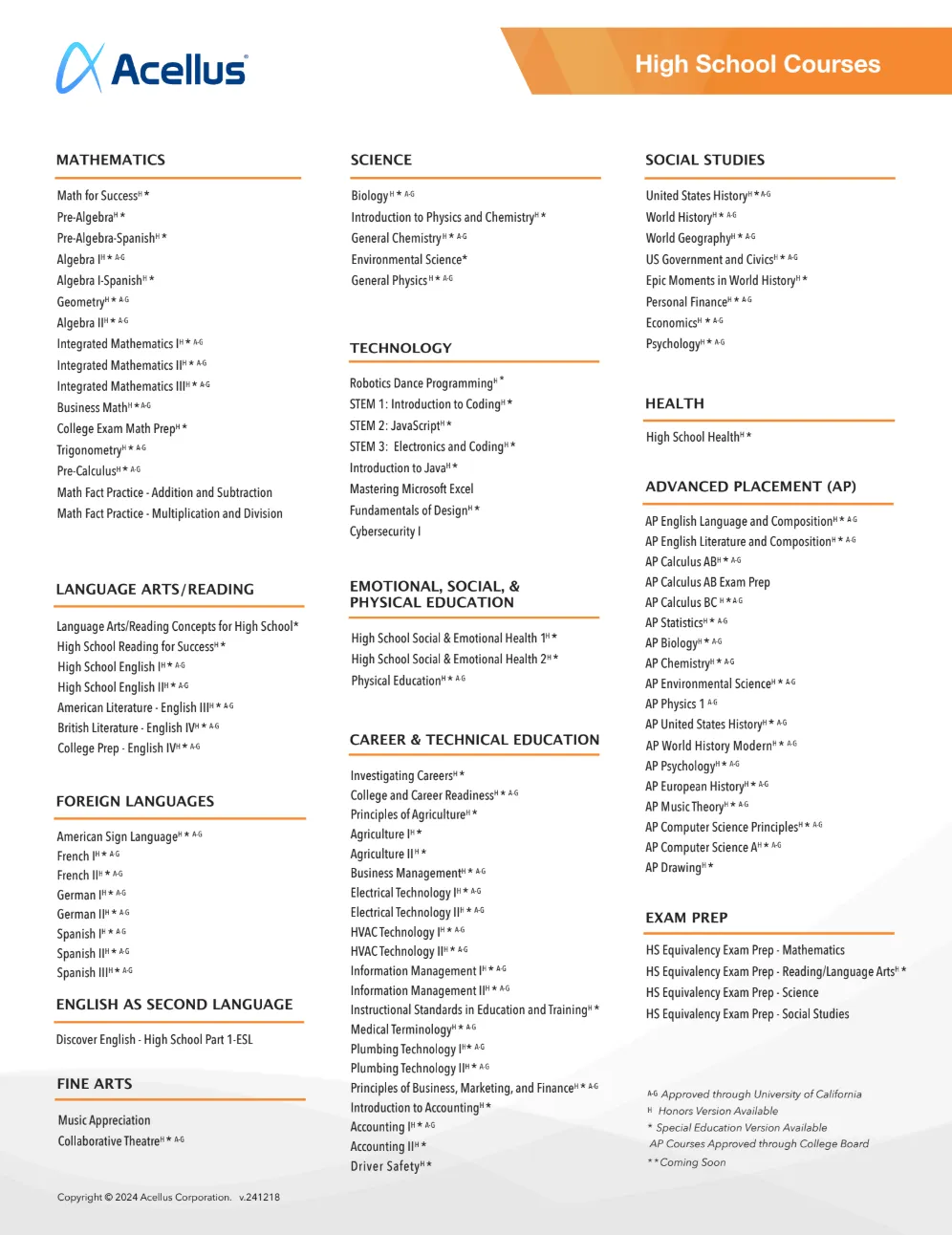

We’ve partnered with Acellus Academy to offer a fully accredited, NCAA-approved academic program designed for athletes. With flexible, self-paced learning, our players can train, compete, and still stay on track academically.

Flexible, self-paced learning

NCAA-approved coursework

Accredited by WASC

Engaging video-based instruction

There is world-class academic support for your student. This isn't a program that is taxing on the parents.

structured for growth

A daily rhythm that builds champions—in the gym, in the classroom, and in life.

At St. Christopher Academy, no hour is wasted. Every part of the day is designed to elevate performance, sharpen discipline, and prepare student-athletes for what’s next. From morning skill work to afternoon coursework and team sessions, we build routines that build results.

A Typical Day at St. Christopher Academy

6:00 AM – Basketball-Specific Small Group Training

8:00 AM – Weight Training & Performance Work

9:00 AM – Breakfast & Nutrition

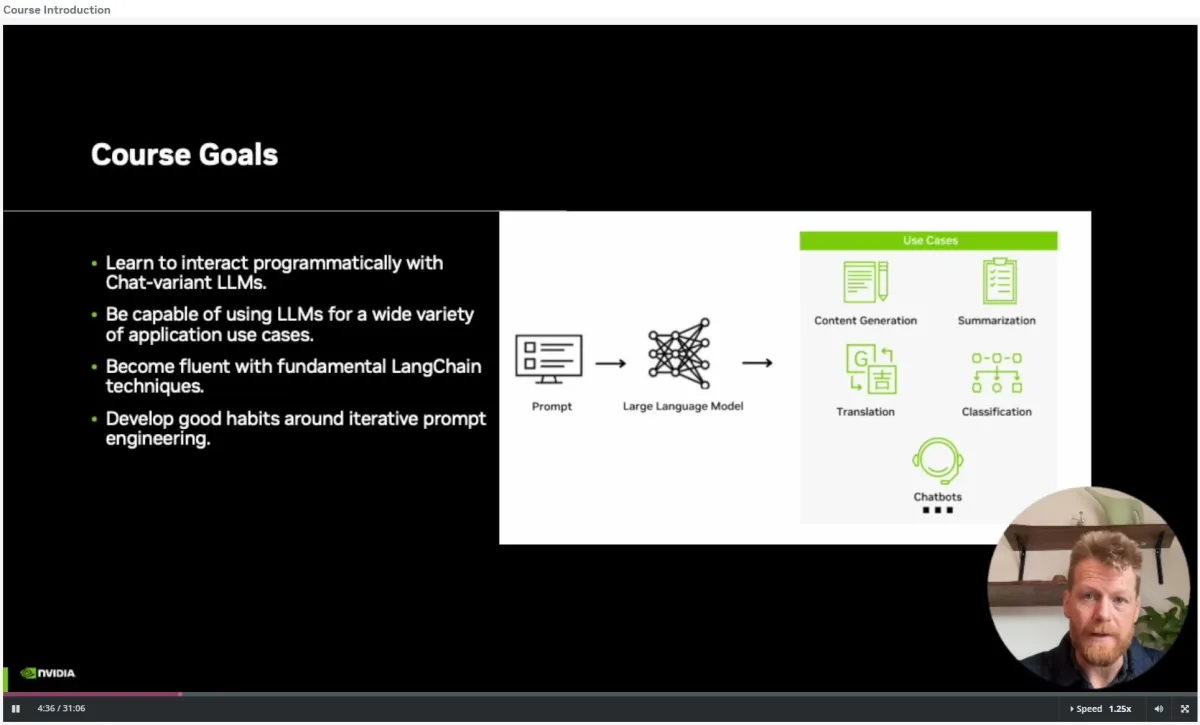

9:30 AM – Generative A.I. & LLM Studies (Optional)*

10:00 AM – Academic Coursework

1:00 PM – Lunch & Recovery

2:00 PM – Team Practice & Conceptual Instruction

4:30 PM – End of Day / Optional Recovery

* Students will have the opportunity to dive into cutting‑edge AI tools from Google and NVIDIA in a focused, self‑guided session. These short, high‑impact courses teach the theory behind generative models and LLMs, plus hands‑on skills in prompt engineering, multimodal AI, and deployment workflows.

Why it matters: In just 30 minutes, students gain practical fluency with the AI tech reshaping every industry—building valuable skills, boosting confidence, and reinforcing our mission to prep winners on and off the court.

Winning on and off the Court

Brian’s impact extends far beyond the gym. As the Athletic Director and Head Basketball Coach at Word of God Christian Academy, he led his teams to over 100 victories, developing players who earned spots at Division 1 programs like UNC Chapel Hill, NC State, Kentucky, and the University of Arizona.

He’s also shared his expertise on an international stage, coaching and inspiring at high-profile events like:

The adidas China Top Prospects Camp

The Down Under Sports Tournament in Australia

This isn’t just coaching—it’s creating a ripple effect of growth and achievement. Real relationships with real coaches translates to real guidance on what's important in youth basketball development.

Former NBA head coach (Golden State Warriors, Cleveland Cavs & Sacramento Kings), Current Coach of Utah Prep, Keith Smart and Brodie Clifton

Memphis Tigers head coach Penny Hardaway and Brodie Clifton breaking down game film.

Kansas Jayhawks assistant coach Kurtis Townsend, Brodie Clifton, & Head Coach Bill Self

Commitment to Excellence and Safety

Brian’s dedication to his craft has earned him recognition as one of the 50 Most Influential People in College Basketball History by Bleacher Report. But what sets him apart is his relentless focus on effort, teamwork, and resilience.

With his USA Basketball Gold Coach License, Brian ensures every player trains in a safe, supportive environment designed to maximize their potential. For him, it’s not just about winning games—it’s about building the confidence and character that last a lifetime.

World-class training facilities

Through our exclusive partnership with Lifetime Fitness, our athletes have access to state-of-the-art training facilities, including elite-level strength and conditioning equipment, recovery amenities, and performance training programs.

Strength & conditioning

Professional-grade recovery amenities

Access to top-tier gym facilities

Convenient Locations & Multisite Access

More Than Just Basketball—Here’s What Your Child Will Gain

Competitive Play

Your child will have the opportunity to compete against top-tier teams in a private school circuit, gaining real-world experience that helps them grow as players.

Personalized Coaching

Coach Clifton’s program focuses on individualized skill development. Whether your child needs to improve their shooting, defense, or overall game IQ, they’ll get the attention they need to succeed.

Balanced Life

We respect the importance of academics, which is why our program is designed to complement your child’s school schedule.

Lessons for Life

Basketball is more than just a game—it’s a way to build character, resilience, and leadership. Coach Clifton’s influence goes beyond the court, helping your child grow in ways that will benefit them for years to come.

Ready for the Next Step? Here’s Why Saint Christopher Academy Stands Out

If your child has the heart and determination to keep pushing forward, even when faced with setbacks, Saint Christopher Academy is the place for them. We’re here for the players who are willing to work hard. Under Coach Clifton’s leadership, they’ll be coached by someone who understands what it means to turn obstacles into opportunities—and they’ll be part of a team that’s about more than just basketball.

Coach Clifton’s story isn’t just about winning games—it’s about proving that when someone believes in you, there’s no limit to what you can achieve.

TUITION BREAKDOWN

NCAA Pathway Focused with Structured Academic and Athletic Alignment

DEVELOPMENT TIER

$750/month

TRAINING & LOCAL GAMES

PROFESSIONAL COACHING

ACELLUS ACADEMIC ENROLLMENT

STRENGTH & CONDITIONING

FOR AGES 12 AND UNDER

VARSITY TIER

$1,250/month

TRAINING & LOCAL GAMES

PROFESSIONAL COACHING

ACELLUS ACADEMIC ENROLLMENT

STRENGTH & CONDITIONING

HANDS ON COLLEGE PLACEMENT AND NCAA ELIGIBILITY SUPPORT

FOR AGES 13 AND UP

NCAA TIER

$1,500/month

TRAINING & LOCAL GAMES

PROFESSIONAL COACHING

ACELLUS ACADEMIC ENROLLMENT

STRENGTH & CONDITIONING

HANDS ON COLLEGE PLACEMENT AND NCAA ELIGIBILITY SUPPORT

TRAVEL - NATIONAL & INTERNATIONAL COMPETITION

OPTIONAL ADD-ONS

NUTRITIONAL MEAL PLANNING

RECOVERY & REHAB

Take the First Step Toward Success—Apply to Saint Christopher Academy Today

Is your child ready to take the next step in their basketball journey? Complete the application today and give them the opportunity to train with Coach Brian Clifton and his team at Saint Christopher Academy. This is their chance to play, grow, and show what they’re made of.

100% SECURE. WE VALUE YOUR PRIVACY.

By submitting your email address and phone number in the form(s) on our site, you give consent to receiving occasional emails and SMS text messages with team announcements or other information.

© 2025 D-ONE Sports